Welcome to

OMC Thermochemistry

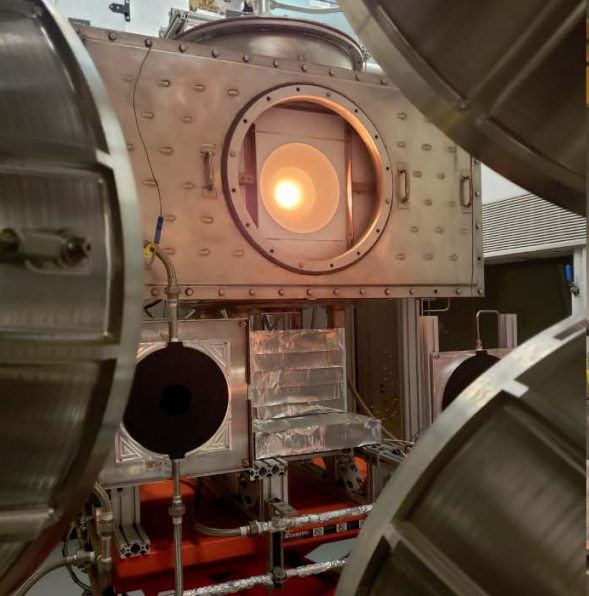

Low cost transformation of carbon dioxide into fuels and chemicals and production of green hydrogen at industrial scales

Our Technology

OMC’s revolutionary process produces green hydrogen and syngas efficiently, at process-relevant pressures, all with zero emissions. It builds off existing industrial processes, which allows for efficient scaling and economies of scale.

Discover the

Future of Energy

Learn more about our innovative process, backed by decades of PhD, peer-reviewed research.

Meet the Team

-

Britt Boughey

CO-FOUNDER

Led Navy portion of $510 million effort to fund advanced drop-in biofuel refineries; broadly connected and experienced across conventional and renewable fuels producers

Orchestrated acceptance and use of 230 million gallons of renewable diesel fuel blends into the fleets of 31 countries

Worked both sides of fundraising table for multiple renewable fuels ventures

Combat-proven Navy F/A-18E/F pilot

-

Dr. Kent Warren

CO-FOUNDER, CHIEF SCIENCE OFFICER

Published and patented expert in high-temperature thermochemistry with over a decade of experience in developing technologies that leverage renewable sources of high-quality heat for the production of value-added commodities

Co-developed and characterized the novel thermochemical platform that enables OMC Thermochemistry's breakthrough energy efficiencies

-

Dr. Juan Inga

LEAD PROCESS ENGINEER

30+ years’ experience in gasification, F-T, piloting, and fluidized beds

-

Dr. Jay Muthusamy

SENIOR MECHANICAL ENGINEER

15+ yrs professional experience in CFD

-

Patrick Vincent

SENIOR PROCESS ENGINEER

6+ yrs leading projects at ExxonMobil

-

Liam Taylor

PROCESS ENGINEER

Led undergraduate research for OMC on active material and process integration